+8618537309624

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

+8618537309624

The DataFlex heat transfer printing intelligent code printer provides super long normal operation time, and low cost of use, can meet all kinds of flexible packaging printing needs. The patented non-clutch ribbon drive maintains consistent ribbon tension and avoids ribbon damage completely, providing superior uptime while ensuring high quality printing. The DataFlex heat transfer printing intelligent printer with 32 mm and 53 mm printing width, can achieve the optimal combination of print head and bandwidth, thus providing the most cost-effective solution for your application. The Data Flex heat transfer printer is designed for applications such as vertical molding, filling and sealing, with a printing speed of up to 250 packs per minute, and offers a range of ribbon saving modes to reduce printing costs.

Please click the button below to receive the free consumable samples

| Availability: | |

|---|---|

Product Description

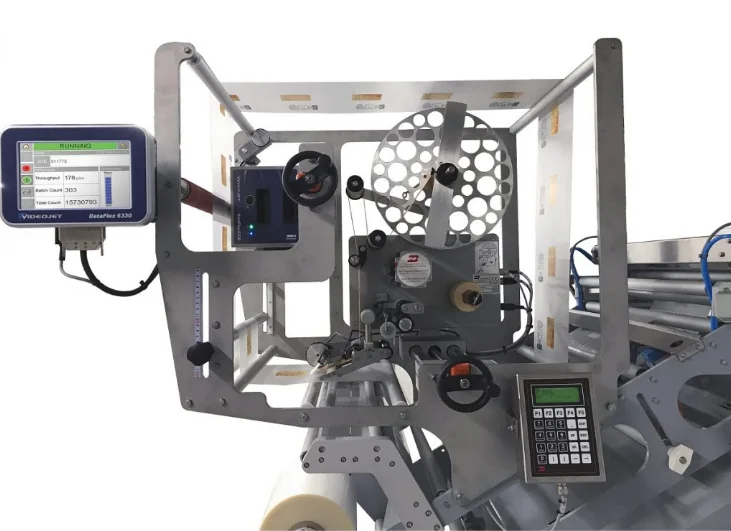

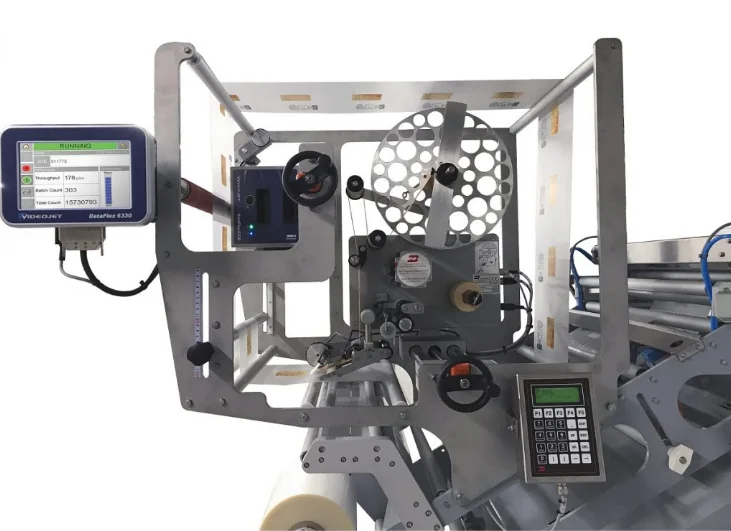

Videojet DataFlex 6330 printer is a transparent advanced coding solution machine

combines the need for code accuracy with the even higher quality technology,

| Printing speed intermittent mode | up to 600 mm/S |

| Printing speed continuous mode | 30 to 600 mm/S |

| Printing area intermittent mode | 53mm or 32mmx75mm |

| Printing area continuous mode | 53mm or 32mmx200mm |

| Max Length TTO ribbon | 1200Meters |

| Type | Intermittent /Continuous |

Detailed Images

Videojet 6330

* iAssure™ technology automatically detects common print defects, reducing unwanted waste

or reworked product, and additional manpower time to correct the error*

* CLARiTY™ software helps ensure the right code is consistently printed on the right product* Intelligent Motion™ technology removes the need for compressed air and associated costs

and downtime, maximizing consistent print quality and printhead life

* Discover code legibility issues that indicate the potential need for printer maintenance* Industry leading simple change cassette is designed for fast ribbon replacement to maximise

uptime

* High ribbon capacity and a variety of ribbon economy modes maximising the time between

ribbon changeovers

* Code quality is automatically maintained and avoids the risk of operators over-adjusting

conventional air and energy settings

* Quick change printhead and minimal wear parts reduce the time production is interrupted

when replacements are required

* Easy to load cassetteDirection for Use

1. The introduction of intelligent printhead,

with automatic setting and bad point detection

function, can meet the requirements of

high-quality printing

3. Left & right hand machines – changeable on site

Featuring a 53mm printhead that performs both intermittent printing and continuous printing

at a maximum speed of 750mm/second,the 6330 is built with an intelligent design to withstand

tough production line environments, and intelligent maintenance with minimal parts wear and

easy to change ribbons.

The Videojet dataFlex® 6330 comes standard with Videojet iAssure™ code quality assurance

technology,

which automatically detects common print defects, helping to ensure high-quality codes are

applied to your packages time after time.* Combined with our CLARiTY™ software, the 6330

reduces the potential for print and coding errors, reducing waste and rework with no extra

manpower or equipment.

Packing & Delivery

One cartoon= one pcs machine

After Sales Service

4.We also sell other brand TTO printer,like markem x40/ 8018 /x65 printer,vidoejet 6530 and so on,

also sell the machine parts,including bracket(frame),printhead,rubber roll,PCB board, synchronizer etc.

Product Description

Videojet DataFlex 6330 printer is a transparent advanced coding solution machine

combines the need for code accuracy with the even higher quality technology,

| Printing speed intermittent mode | up to 600 mm/S |

| Printing speed continuous mode | 30 to 600 mm/S |

| Printing area intermittent mode | 53mm or 32mmx75mm |

| Printing area continuous mode | 53mm or 32mmx200mm |

| Max Length TTO ribbon | 1200Meters |

| Type | Intermittent /Continuous |

Detailed Images

Videojet 6330

* iAssure™ technology automatically detects common print defects, reducing unwanted waste

or reworked product, and additional manpower time to correct the error*

* CLARiTY™ software helps ensure the right code is consistently printed on the right product* Intelligent Motion™ technology removes the need for compressed air and associated costs

and downtime, maximizing consistent print quality and printhead life

* Discover code legibility issues that indicate the potential need for printer maintenance* Industry leading simple change cassette is designed for fast ribbon replacement to maximise

uptime

* High ribbon capacity and a variety of ribbon economy modes maximising the time between

ribbon changeovers

* Code quality is automatically maintained and avoids the risk of operators over-adjusting

conventional air and energy settings

* Quick change printhead and minimal wear parts reduce the time production is interrupted

when replacements are required

* Easy to load cassetteDirection for Use

1. The introduction of intelligent printhead,

with automatic setting and bad point detection

function, can meet the requirements of

high-quality printing

3. Left & right hand machines – changeable on site

Featuring a 53mm printhead that performs both intermittent printing and continuous printing

at a maximum speed of 750mm/second,the 6330 is built with an intelligent design to withstand

tough production line environments, and intelligent maintenance with minimal parts wear and

easy to change ribbons.

The Videojet dataFlex® 6330 comes standard with Videojet iAssure™ code quality assurance

technology,

which automatically detects common print defects, helping to ensure high-quality codes are

applied to your packages time after time.* Combined with our CLARiTY™ software, the 6330

reduces the potential for print and coding errors, reducing waste and rework with no extra

manpower or equipment.

Packing & Delivery

One cartoon= one pcs machine

After Sales Service

4.We also sell other brand TTO printer,like markem x40/ 8018 /x65 printer,vidoejet 6530 and so on,

also sell the machine parts,including bracket(frame),printhead,rubber roll,PCB board, synchronizer etc.

Videojet 6330

Code Assurance

* iAssure™ technology automatically detects common print defects, reducing unwanted waste or reworked product, and additional

manpower time to correct the error*

* CLARiTY™ software helps ensure the right code is consistently printed on the right product

Uptime advantage

* Intelligent Motion™ technology removes the need for compressed air and associated costs and downtime, maximizing consistent

print quality and printhead life

* Discover code legibility issues that indicate the potential need for printer maintenance

* Industry leading simple change cassette is designed for fast ribbon replacement to maximise uptime

* High ribbon capacity and a variety of ribbon economy modes maximising the time between ribbon changeovers

Easy usability

* Designed to withstand tough production line environments

* Minimal wear parts are easy to change out, improving production line uptime

* Compact design fits on almost all production lines

* Simple operator interface

Built-in productivity

* The electronic printhead control eliminates the need for compressed air

* Code quality is automatically maintained and avoids the risk of operators over-adjusting conventional air and energy settings

* Quick change printhead and minimal wear parts reduce the time production is interrupted when replacements are required

* Easy to load cassette

Videojet 6330

Code Assurance

* iAssure™ technology automatically detects common print defects, reducing unwanted waste or reworked product, and additional

manpower time to correct the error*

* CLARiTY™ software helps ensure the right code is consistently printed on the right product

Uptime advantage

* Intelligent Motion™ technology removes the need for compressed air and associated costs and downtime, maximizing consistent

print quality and printhead life

* Discover code legibility issues that indicate the potential need for printer maintenance

* Industry leading simple change cassette is designed for fast ribbon replacement to maximise uptime

* High ribbon capacity and a variety of ribbon economy modes maximising the time between ribbon changeovers

Easy usability

* Designed to withstand tough production line environments

* Minimal wear parts are easy to change out, improving production line uptime

* Compact design fits on almost all production lines

* Simple operator interface

Built-in productivity

* The electronic printhead control eliminates the need for compressed air

* Code quality is automatically maintained and avoids the risk of operators over-adjusting conventional air and energy settings

* Quick change printhead and minimal wear parts reduce the time production is interrupted when replacements are required

* Easy to load cassette

Featuring a 53mm printhead that performs both intermittent printing and continuous printing at a maximum speed of 750mm/second,the 6330 is built with an intelligent design to withstand tough production

line environments, and intelligent maintenance with minimal parts wear and easy to change ribbons. The Videojet dataFlex® 6330 comes standard with Videojet iAssure™ code quality assurance technology,

which automatically detects common print defects, helping to ensure high-quality codes are applied to your packages time after time.* Combined with our CLARiTY™ software, the 6330 reduces the potential for print and coding errors, reducing waste and rework with no extra manpower or equipment.

Featuring a 53mm printhead that performs both intermittent printing and continuous printing at a maximum speed of 750mm/second,the 6330 is built with an intelligent design to withstand tough production

line environments, and intelligent maintenance with minimal parts wear and easy to change ribbons. The Videojet dataFlex® 6330 comes standard with Videojet iAssure™ code quality assurance technology,

which automatically detects common print defects, helping to ensure high-quality codes are applied to your packages time after time.* Combined with our CLARiTY™ software, the 6330 reduces the potential for print and coding errors, reducing waste and rework with no extra manpower or equipment.

One cartoon= one pcs machine

About is 20kg,pack size:60*37*39cm

One cartoon= one pcs machine

About is 20kg,pack size:60*37*39cm

1.We provide videos and instruction manual to show the process of installation

2.The machine will have one year warranty .

3. Free lifetime technique support.

4.We also sell the machine parts,including bracket(frame),printhead,rubber roll,PCB board, synchronizer etc.

1.We provide videos and instruction manual to show the process of installation

2.The machine will have one year warranty .

3. Free lifetime technique support.

4.We also sell the machine parts,including bracket(frame),printhead,rubber roll,PCB board, synchronizer etc.

Width: 25mm 30mm 35mm 40mm 45mm 50mm 840mm

Length: 100M 120M 122M 150M 183M 200M 300M 4500M

Coding foil can be used on DY-8 handheld printer, HP-241B semi-automatic coding machine, HP-241 pillow type coding machine, ect.

Hot ink roll is to print date and batch number on food or medical packages.

Size: Dia36*16 Dia36*32 Dia36*36 Dia36*40

Color: Black Red White Blue

Please click the button below to receive the free consumable samples

the machine Compact in structure, convenient in assembling and using, fast in printing with large printing cover, flexible in formatting types, and much shorter in the minimum printing distance, it has widely used in food and drug.

Please click the button below to receive the free consumable samples

The DataFlex heat transfer printing intelligent code printer provides super long normal operation time, and low cost of use, can meet all kinds of flexible packaging printing needs. The patented non-clutch ribbon drive maintains consistent ribbon tension and avoids ribbon damage completely, providing superior uptime while ensuring high quality printing. The DataFlex heat transfer printing intelligent printer with 32 mm and 53 mm printing width, can achieve the optimal combination of print head and bandwidth, thus providing the most cost-effective solution for your application. The Data Flex heat transfer printer is designed for applications such as vertical molding, filling and sealing, with a printing speed of up to 250 packs per minute, and offers a range of ribbon saving modes to reduce printing costs.

Please click the button below to receive the free consumable samples

Tto ribbon is the near edge TTO ribbon.

It is used on LINX TT500,/TT750/TT1000/TT3/TT5/TT10, Markem 8018/X30/X40/X45/X60/X65, Videojet 6530/6330/6230, and Domino V120i/230i/320i Printer to print Date, Bar code, Lot number, Production date.

Please click the button below to receive the free consumable samples

Markem 8018 Excellent print quality The printing quality of the whole roll of ribbon will never fade It can improve your company's brand image and quality.

The introduction of intelligent printhead, with automatic setting and bad point detection function, can meet the requirements of high-quality printing

Please click the button below to receive the free consumable samples

This electric thermal coder uses automatic continuous printing. It can also be printed by foot switch. Reasonable structure, excellent design, precise processing, high quality quality make you feel comfortable with peace of mind. This machine has the functions of printing production date, expiration date, batch number, etc. The printing is clear and firm, and the writing is clear. Does not fall off. Widely used in food, medicine, leather, plastic bags, cartons, skin care products, health products, daily necessities, etc

Please click the button below to receive the free consumable samples

1.Printing on any packaging materials,clear and not easy to scrape,sanitary and clean.It run with the main frame, convenient installment and adjustment..

2..Automatic electric ribbon coding machine suitable for all kinds of packing machine.

3.It can be equipped with all kinds of flow packing machine and continuously vertical packing machine for tracing and printing production date,lot number,expire date.

4.Character moulds need to be customized: 0-9 a-z A-Z . / etc. 2*3*15mm/2*4*15mm for choose.

Please click the button below to receive the free consumable samples

Markem Smartdate X45 is a transparent advanced coding solution machine.Designed for medium-duty applications, the SmartDate X45 delivers high-quality coding on flexible film packaging up to 220 packs per minute.

Please click the button below to receive the free consumable samples

The Linx TT Series of thermal transfer overprinters provides an ideal printing solution onto flexible packaging across a wide variety of industrial applications. Designed to deliver a low total cost of ownership and increase your production line output, the Linx TT Series printers are particularly suitable for printing consistent, error free best before dates, batch

codes, barcodes, ingredients, logos and other product information.

Please click the button below to receive the free consumable samples